Cross ventilation is an essential technique in many industrial environments, especially warehouses, where air quality and temperature control are crucial. This method involves the natural movement of air through a building, using specific openings to allow air in and out, ensuring constant renewal. In industrial warehouses, where ventilation can become a challenge due to the size and layout of the space, implementing efficient cross ventilation can bring numerous benefits, from reducing energy costs to improving thermal comfort and workers’ health.

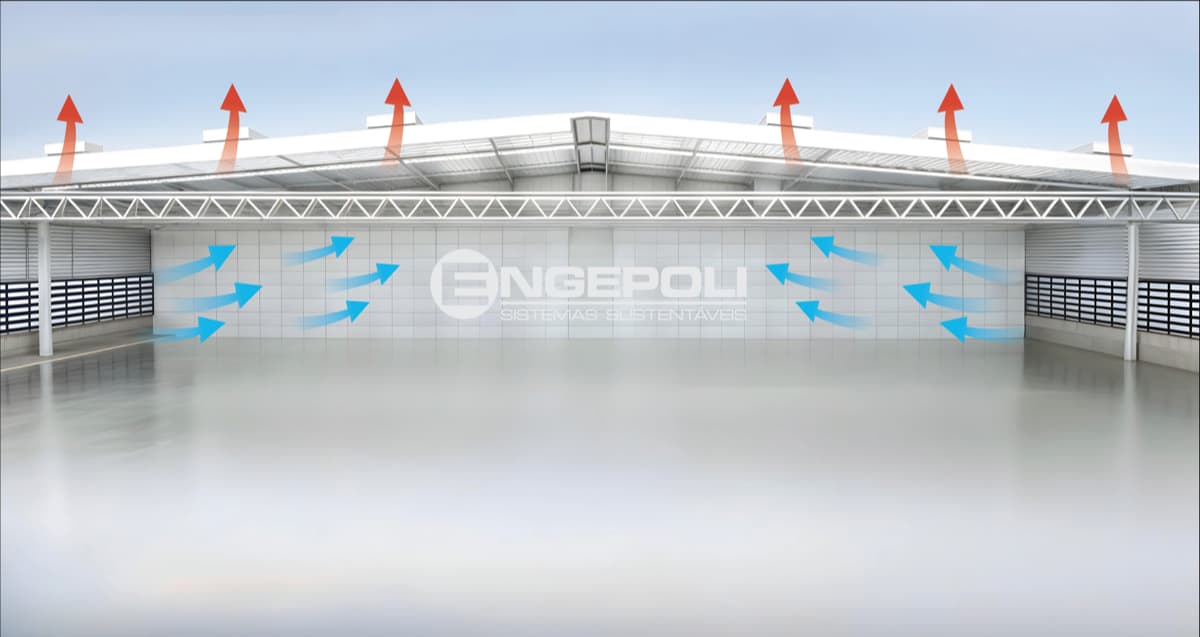

Cross ventilation is a natural ventilation process that promotes the circulation of fresh air through a space, expelling hot, stagnant air. This process occurs when air enters through an opening, usually in a wall or window, and exits on the opposite side, or on the roof, creating a constant flow of air.

Technically, cross ventilation takes advantage of differences in pressure and temperature to move air from one point to another through the effect of convection. Air flows naturally from areas of high pressure (usually on the upwind side) to areas of low pressure (on the opposite side). This continuous flow helps to renew indoor air, reducing the concentration of pollutants and improving environmental quality.

Imagine a shed with windows or vents strategically positioned on opposite walls. When the wind blows from one direction, it enters through the upwind vents, travels around the inside of the shed and exits through the vents on the opposite side or the roof. This continuous movement reduces the need for mechanical ventilation systems, promoting energy efficiency and a healthier working environment.

More than just air movement, cross-ventilation can be adapted to various situations, including different warehouse configurations, types of stored products and climatic conditions. Some of the techniques include the use of natural exhaust fans, lanterns, and fans strategically positioned to maximize the effectiveness of the air flow.

One of the greatest advantages of cross ventilation is the effective renewal of indoor air. In industrial environments, where intense activity can generate heat and release particles into the air, cross ventilation promotes constant air exchange, evacuating hot, polluted air and bringing in fresh air from outside. This process keeps air quality at optimum levels, preventing the concentration of harmful substances and promoting a healthier environment for everyone.

Another significant benefit is the reduction in energy costs. Industrial warehouses often rely on mechanical ventilation and cooling systems to maintain the right conditions. However, these systems are notoriously expensive in terms of energy consumption. Implementing efficient cross-ventilation can minimize the need for these devices, taking advantage of the natural dynamics of wind and atmospheric pressure to keep the environment ventilated and pleasant, resulting in substantial energy savings.

Air quality is a constant concern in industrial environments. Cross ventilation helps remove pollutants, dust and other contaminants from the air. By providing a continuous flow of fresh air, the accumulation of toxic agents is minimized and the working environment is significantly improved. This continuous air movement is especially effective in reducing levels of CO2 and other gases that can accumulate in enclosed spaces.

In addition to the technical aspects, thermal comfort is a crucial factor for worker productivity. When the environment is well ventilated, thermal conditions are more stable and comfortable, avoiding heat overload which can cause fatigue and decrease efficiency. Studies show that environments with good natural ventilation, such as cross ventilation, improve the thermal sensation and general well-being of workers, promoting greater productivity and job satisfaction.

| ASPECT | PERCENTAGE | DESCRIPTION |

| Energy saving | Average 30% reduction in energy bills | Companies that have implemented cross-ventilation have seen an average 30% reduction in energy costs related to ventilation and cooling. |

| Dependence on fans/air conditioning | Up to 20% less use of air conditioning | Case studies show that industrial warehouses have reduced their dependence on fans and air conditioning by up to 20% during the hottest months. |

| Improved Air Quality | Up to 50% fewer harmful particles in the air | Cross-ventilated environments have shown a reduction of up to 50% in the presence of dust particles and pollutants compared to conventional mechanical ventilation systems. |

| Reduction of CO2 and VOCs | Significant improvement in air quality | Data collected from air quality sensors indicates a significant reduction in CO2 and VOCs (Volatile Organic Compounds), improving the health of the working environment. |

| Worker productivity | 15% increase in productivity | Studies indicate that workers in well-ventilated environments have a 15% increase in productivity, attributed to better thermal conditions and less feeling of heat stress. |

| Reduction in complaints of thermal discomfort | 25% reduction in complaints | Complaints related to discomfort due to heat decreased by 25% after the implementation of cross-ventilation systems. |

Implementing effective cross-ventilation in industrial warehouses requires meticulous planning and a thorough understanding of airflow dynamics and the specifics of the environment. Below, we present guidelines to ensure that cross-ventilation is optimized for maximum benefits.

The architectural design of the shed is a crucial factor in the success of cross ventilation. Here are some important considerations:

The correct positioning of windows and openings is key to ensuring air flow. Here are the best practices:

To optimize cross ventilation, consider the following tips based on the orientation of the shed and local climatic conditions:

By following these guidelines, it is possible to implement a highly effective cross-ventilation system in industrial warehouses, ensuring a healthier and more efficient environment.

Implementing cross-ventilation in industrial warehouses can be challenging due to various factors, including the structure of the building, local climatic conditions and the specific needs of the operation. Below, we discuss some of the most common challenges and how to overcome them, as well as highlighting technologies and products from Engepoli that can help with effective implementation.

| CHALLENGE | DESCRIPTION | SOLUTION |

| Shed structure | Many industrial warehouses have complex structures, such as internal partitions, ceilings and bulky machinery, which can obstruct the flow of natural air, making cross-ventilation difficult. | Structural assessment: Carry out a detailed assessment of the shed structure to identify obstructed areas. Layout design: Reconfigure the internal layout to minimize obstructions to airflow. This can include rerouting machinery or opening up new ventilation corridors. |

| Climate and Location | Unfavorable weather conditions, such as low winds or extreme climates, can prevent effective cross-ventilation. | Climate adjustments: Use auxiliary fans and exhaust fans to supplement natural ventilation in regions with low winds. Adaptive technology: Install automated controls to adjust ventilation openings as weather conditions change. |

| Thermal insulation | Sheds with inadequate thermal insulation can suffer from extreme internal temperatures, reducing the effectiveness of natural ventilation. | Adequate insulation: Improve the thermal insulation of the shed by using appropriate materials in the walls and roof. Thermal barriers: Adopt thermal barriers combined with cross ventilation to maximize temperature control. |

| Initial costs | The initial costs of renovating and installing improved ventilation systems can be prohibitive. | Cost-benefit analysis: Carry out a detailed cost-benefit analysis to justify the initial investment with energy savings and long-term productivity improvements. Modular solutions: Implement ventilation solutions in stages, using products that can be installed incrementally as the budget allows. |

Engepoli offers customized solutions based on the specific needs of your project. Specialized consulting services ensure that each installation is optimized for maximum efficiency. Check it out:

Using industrial shutters, this system guarantees superior natural lighting compared to other materials such as PVC and fiberglass. This system is specially designed to meet the needs of industrial environments, where both lighting and ventilation are crucial to well-being and productivity.

Luxvent uses high-quality materials and advanced technology to maximize the entry of natural light while promoting air circulation, resulting in superior thermal and visual comfort.

Benefits of Luxvent:

Find out more about this solution.

This system is specifically designed to optimize cross-ventilation in large industrial spaces. Composed of natural exhaust fans that do not require electricity, it uses the difference in pressure to expel hot air and introduce fresh air.

Advantages of the System Exhaust:

Find out more about this solution.

By addressing common challenges with practical and reliable solutions, and by using the advanced technologies and products of Engepoli, it is possible to implement effective cross-ventilation in any industrial shed, promoting a healthy and efficient working environment with significant energy savings.

Cross ventilation has emerged as a powerful and indispensable tool for industrial warehouses, providing a series of benefits that go beyond simple air flow. In this article, we cover everything from defining the concept and its importance, to efficient implementation and the challenges that can be faced in the process. The constant renewal of indoor air, reduced energy costs and improved air quality stand out as significant advantages, contributing directly to a safer and more comfortable working environment.

The integration of specific solutions, such as the Industrial Shutters Luxvent and the Natural Ventilation System Exhaust from Engepoli, demonstrates that it is possible to combine technological innovation with sustainability and operational efficiency. Careful consideration of architectural design and the strategic positioning of openings also ensure that airflow is optimized for maximum benefit.

If you’re looking to transform your industrial warehouse into a healthier, more energetic and productive environment, Engepoli is here to help. Our expertise in natural and sustainable ventilation solutions, combined with our patented products and specialized technical support, guarantees that you will achieve the best results.

Contact Engepoli for a personalized consultation. Our team of experts is ready to help you implement the best practices and technologies to maximize energy efficiency, improve air quality and ensure a healthier and more productive working environment. Click here to schedule a visit or request a quote!

Index source:

https://sustainablebuildingsinitiative.org/toolkits/emissions-reduction-toolkits/energy-efficiency/office-design/?toolkit=197

https://greenhome.osu.edu/natural-ventilation

By using this site you accept the use of cookies to optimize your browsing experience. Privacy Policy